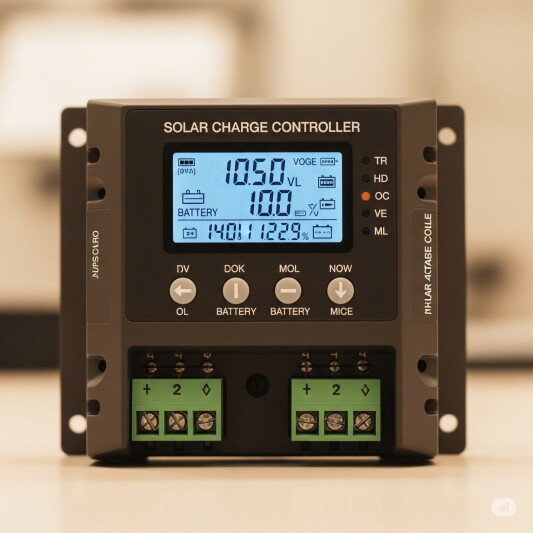

Charge controller solar

What is a Solar Charge Controller?

A solar charge controller is an essential device used in off-grid solar power systems. It sits between the solar panels and the battery bank, and its main role is to regulate the charging process to ensure batteries are charged efficiently and safely.

Main Functions:

Prevents overcharging of batteries

Prevents deep discharging, which can damage batteries

Stops reverse current flow from batteries back to the solar panels at night

Monitors voltage and current levels for system safety

What is a Solar Charge Controller?

A solar charge controller is an essential device used in off-grid solar power systems. It sits between the solar panels and the battery bank, and its main role is to regulate the charging process to ensure batteries are charged efficiently and safely.

Main Functions:

Prevents overcharging of batteries

Prevents deep discharging, which can damage batteries

Stops reverse current flow from batteries back to the solar panels at night

Monitors voltage and current levels for system safety