SCADA in Water Treatment: Why It Matters

🔹 1. What Is SCADA?

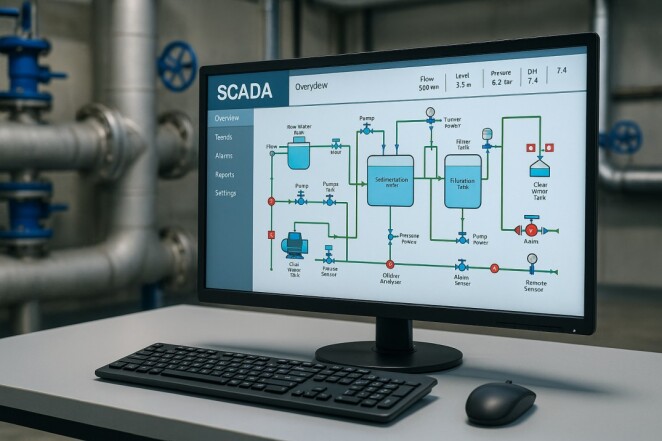

In today’s modern water and wastewater treatment plants, automation is no longer a luxury — it's a necessity. At the heart of this automation lies SCADA (Supervisory Control and Data Acquisition), a powerful system that allows operators to monitor, control, and optimize plant operations in real time. But what exactly is SCADA, and why is it so critical in the water industry?

SCADA is a centralized system that gathers data from various equipment — sensors, pumps, valves, tanks, analyzers — and presents it visually through Human-Machine Interfaces (HMIs). It allows operators to remotely:

Monitor real-time performance

Adjust setpoints or commands

Receive alarms or warnings

Analyze historical data and trends

In a water treatment context, SCADA integrates every key process, from raw water intake to filtration, chemical dosing, storage, and distribution.

🔹 2. Real-Time Monitoring & Control

SCADA provides a real-time window into the health of your plant:

Flow rates, pressure, chlorine levels, pH, and tank levels are constantly tracked.

Operators can respond instantly to abnormal conditions such as a pump failure, low chlorine residual, or filter overload.

Remote access via web or mobile lets supervisors manage the plant 24/7 — even from off-site.

This level of visibility prevents breakdowns and improves operational efficiency.

🔹 3. Automation Improves Consistency and Safety

Manual operation leaves room for error. With SCADA, systems can operate automatically based on pre-programmed logic:

Chemical dosing adjusts in real-time based on flow and sensor feedback.

Pump operation can cycle based on reservoir levels or pressure demands.

Alarms are triggered before critical failures happen.

This improves process stability, reduces human error, and ensures regulatory compliance.

🔹 4. Historical Data & Reporting

SCADA systems store large amounts of data — which can be used for:

Trend analysis: Detect patterns in water quality or energy use.

Regulatory reporting: Automatically generate daily or monthly compliance logs.

Maintenance planning: Identify when equipment performance is degrading.

Instead of reacting to problems, you can predict and prevent them.

🔹 5. Integration with Other Systems

SCADA is often integrated with:

PLC (Programmable Logic Controllers): For device-level automation

Telemetry systems: For remote sites and lift stations

Asset management software: To connect operations and maintenance teams

A well-integrated SCADA network becomes the digital backbone of the entire utility.

Conclusion

SCADA systems are more than just control panels — they are the nerve center of modern water treatment plants. From enhancing safety and efficiency to enabling smart, data-driven decisions, SCADA transforms the way water utilities operate.

Whether you're upgrading an old system or building a new plant, investing in a robust SCADA platform is one of the smartest moves you can make.

Need help choosing the right SCADA solution? [Contact us]